Exploring the Process of Rotomolding: From Concept to Creation

Plastics happen to be an integral part of our everyday living for years now. We use plastic goods for a number of purposes, whether it is for packing, holding, or elaborate uses. While the creation of plastic material merchandise has evolved over the years, just about the most Rotomolding fascinating types of creating plastic products is Rotomolding. Rotomolding is definitely an art work which involves the warming and molding of plastic materials to make a variety of merchandise. On this page, we shall jump serious into the field of Rotomolding and go over the many aspects of this process.

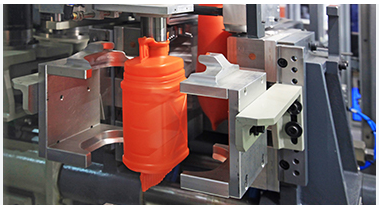

The initial phase along the way of Rotomolding entails the creation of a fungus or tool. The mildew is normally created from aluminum, metallic, or epoxy and it is created based on the required features in the item. As soon as the fungus is created, it is attached to a spinning arm within a equipment referred to as a rotomolding oven. The natural plastic material substance will be included in the mold in both natural powder or liquid kind.

The 2nd stage requires home heating the mildew along with the plastic-type material in the your oven. The temperature during this stage can vary dependant upon the measurements of the mildew and the sort of plastic-type used. Usually, the temperature from the oven can vary from 250 to 400 diplomas Fahrenheit. Home heating the mold and plastic-type to this temperature brings about the plastic-type to melt and follow the mold.

The 3rd stage consists of rotation of the fungus to ensure the plastic-type is consistently spread. The rotation from the cooker is generally accomplished at the speed of 4 to 20 revolutions a minute. This process makes sure that the plastic-type material is evenly dispersed during the entire fungus and that there are no oxygen wallets.

Your fourth period entails cooling down the mildew along with the plastic material. The mildew is taken away from your your oven once the plastic material has solidified and cooled. The cooling method can be completed manually through the use of oxygen and drinking water. As soon as the plastic-type material has cooled, this product is ready to be taken off the mildew. The air conditioning process is crucial since it aids to ensure the plastic material is not going to warp or deform.

The ultimate period consists of cutting any additional plastic-type material through the merchandise. The product will be checked out for almost any defects or defects. Once the product goes by the evaluation, it is able to be packaged and mailed to the ultimate spot.

In short:

Rotomolding is a interesting method that makes plastic-type material merchandise of numerous shapes and sizes. With this particular approach, there are actually no boundaries to the kind of merchandise that may be made. The process is cost-effective and assures producing higher-quality goods. If you are looking to make a plastic material product, Rotomolding is without question an alternative you should consider.